FAQ

The Role of PE Boards in Footwear

PE boards have been a key material in the footwear industry for many years.

A single pair of shoes is made from a variety of materials — ranging from textiles to rubber — with some designs incorporating over 40 different components. Each material serves a specific purpose, contributing to the shoe's structure, comfort, and durability.

While PE boards are commonly associated with industrial applications and home furnishings, many people don't realize they are also widely used in footwear. Their main role is to provide extra support to the midsole and outsole, helping to maintain the shoe's shape and stability. Additionally, they allow upper materials to be securely stitched in place, ensuring long-lasting structure and comfort.

Adrenaline-fueled world of wakeboarding

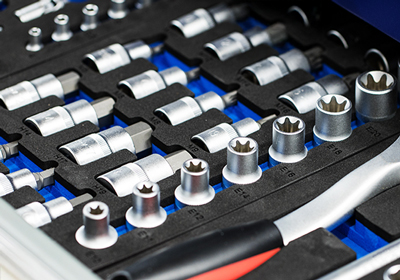

When it comes to tool storage, functionality often comes at the expense of durability and aesthetics. Traditionally, inner trays rely on cut sponges to fix tools and metal components in place. While initially effective, these sponges tend to sink over time from the constant pressure of taking and placing tools. Friction marks appear, dust sticks to the edges, and the clean look of a new toolbox quickly fades. Eventually, the inner layers need to be replaced—not because they stopped working, but because they no longer look or feel right.

This is where our PE board comes in.

By combining customizable softness and hardness in a single solution, our PE board redefines how storage systems can perform. Unlike sponge, it resists deformation, holds its shape, and maintains a sleek appearance over time. It not only protects your tools but also preserves the professional, modern look of your toolbox. No more worn-out interiors, no more frequent replacements—just a long-lasting solution that performs and looks sharp.

Additionally, we can emboss the HDPE surface to make the appearance more decorative designs.

● Providing customized the performance of these composite materials by adjusting the thickness, layering, and combinations of different materials.

● Appearance texture can be designed for a truly personalized solution.

But the story doesn’t end there.

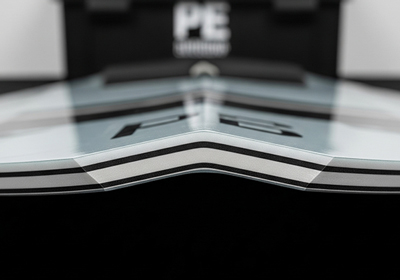

In an unexpected turn, our PE board found its way into the adrenaline-fueled world of wakeboarding. In collaboration with a client, we developed a sandwich composite material—a fusion of decorative film, PE sheet, and sponge bonded in one step. This innovation opened up a whole new arena: PE boards as lightweight, flexible, and resilient materials for sports equipment.

These two examples—toolbox trays and wakeboards—show just how versatile our PE board series can be. From organized storage systems to extreme sports gear, it proves that durability and design don’t have to be separate goals.

We believe this is only the beginning.

We’re continuously exploring new ways to apply our PE technology across industries. If you see a challenge in your product—whether it’s about protection, structure, or aesthetic—we invite you to reach out. Let’s discover the possibilities together.

A single pair of shoes is made from a variety of materials — ranging from textiles to rubber — with some designs incorporating over 40 different components. Each material serves a specific purpose, contributing to the shoe's structure, comfort, and durability.

While PE boards are commonly associated with industrial applications and home furnishings, many people don't realize they are also widely used in footwear. Their main role is to provide extra support to the midsole and outsole, helping to maintain the shoe's shape and stability. Additionally, they allow upper materials to be securely stitched in place, ensuring long-lasting structure and comfort.

Adrenaline-fueled world of wakeboarding

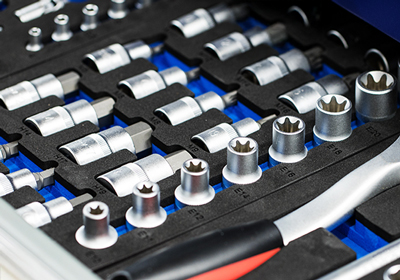

When it comes to tool storage, functionality often comes at the expense of durability and aesthetics. Traditionally, inner trays rely on cut sponges to fix tools and metal components in place. While initially effective, these sponges tend to sink over time from the constant pressure of taking and placing tools. Friction marks appear, dust sticks to the edges, and the clean look of a new toolbox quickly fades. Eventually, the inner layers need to be replaced—not because they stopped working, but because they no longer look or feel right.

This is where our PE board comes in.

By combining customizable softness and hardness in a single solution, our PE board redefines how storage systems can perform. Unlike sponge, it resists deformation, holds its shape, and maintains a sleek appearance over time. It not only protects your tools but also preserves the professional, modern look of your toolbox. No more worn-out interiors, no more frequent replacements—just a long-lasting solution that performs and looks sharp.

Additionally, we can emboss the HDPE surface to make the appearance more decorative designs.

● Providing customized the performance of these composite materials by adjusting the thickness, layering, and combinations of different materials.

● Appearance texture can be designed for a truly personalized solution.

But the story doesn’t end there.

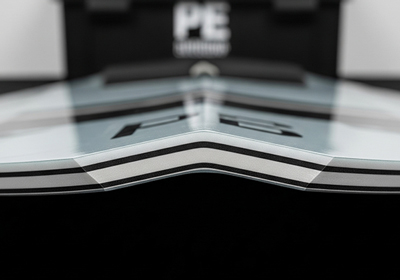

In an unexpected turn, our PE board found its way into the adrenaline-fueled world of wakeboarding. In collaboration with a client, we developed a sandwich composite material—a fusion of decorative film, PE sheet, and sponge bonded in one step. This innovation opened up a whole new arena: PE boards as lightweight, flexible, and resilient materials for sports equipment.

These two examples—toolbox trays and wakeboards—show just how versatile our PE board series can be. From organized storage systems to extreme sports gear, it proves that durability and design don’t have to be separate goals.

We believe this is only the beginning.

We’re continuously exploring new ways to apply our PE technology across industries. If you see a challenge in your product—whether it’s about protection, structure, or aesthetic—we invite you to reach out. Let’s discover the possibilities together.